Email: office@ascopumps.kz

Kazakhstan

Main pageService

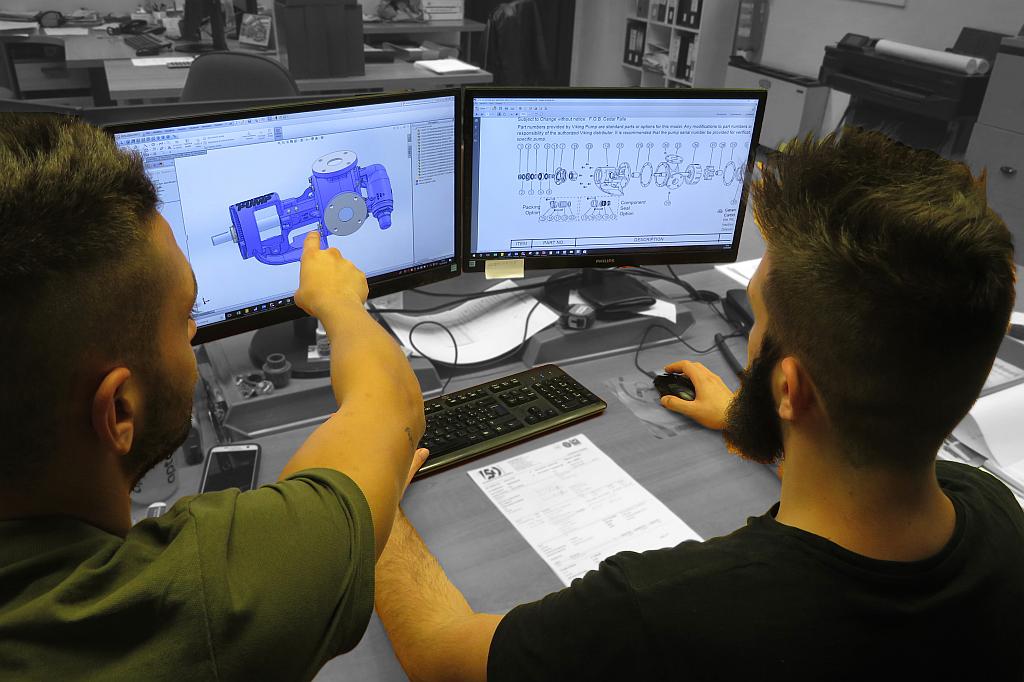

Service and repair of industrial pumps

Modern pumping equipment requires a qualified approach not only at the stage of its selection, but also during installation, operation, maintenance and repair.

ASCO PUMPS strategy in the field of equipment service is to respond promptly to the customer's need for high-quality and reliable service.

Our centre carries out diagnostics, maintenance and repair work on the equipment we supply: pumps, filters, mixers, flow meters. We also accept equipment that was not supplied by us for comprehensive service.

Our centre carries out diagnostics, maintenance and repair work on the equipment we supply: pumps, filters, mixers, flow meters. We also accept equipment that was not supplied by us for comprehensive service.

Experience

.jpg)

Maintenance and repairs are carried out by our own highly qualified service engineers. They are highly specialised mechanical specialists who are able to carry out major repairs and maintenance of pumps and industrial equipment both at our facilities and directly on-site. The equipment is serviced by using tools, auxiliary devices and mounting materials recommended by the manufacturer of the equipment.

Diagnostics

Advanced diagnostics techniques allow the analysis of the operating status of the machines: for example, the use of an electronic analyzer complete with a management program to control vibrations and conditions of the bearings. The purpose is to predict and prevent any machine malfunctions, making it possible to optimize the performance and increase MTBM.

Diagnostics and repair of industrial equipment is carried out promptly and with a quality guarantee. Repairs are carried out in our service center, unless there is a requirement to carry out repairs at the immediate location of the pumping equipment. If necessary, we will consult on the technical features of component materials and assemblies.

ASCO PUMPS service specialists provide equipment maintenance in any region of Kazakhstan. The durability and reliability of the equipment lies in its proper selection, compliance with operating conditions, and qualified service.

ASCO PUMPS service specialists provide equipment maintenance in any region of Kazakhstan. The durability and reliability of the equipment lies in its proper selection, compliance with operating conditions, and qualified service.

Complex of services

ASCO PUMPS service department not only carries out routine repairs and maintenance of pumps, but also provides a range of other services:

- Technical audit of the installed equipment and energy efficiency audit of pumping equipment (for the purpose of further feasibility study of the feasibility of modernising the existing pumping fleet).

- Consultations at the stage of modernisation, reconstruction or installation of new pumping units.

- Acceptance for maintenance of the entire pumping equipment with planning of the technological scheme of its maintenance.

- Conducting trainings for your service personnel, who will operate the equipment in the future.

- Preparing the equipment for commissioning (installation supervision, alignment, adjustment, start-up and checking of operating parameters).

Maintenance & Service Plan

Maintenance & Service Plan identifies the problems before they come up, avoiding unpleasant and often very expensive machine stops. The service, regulated by an annual contract, provides for a periodic monitoring of the plant/system and of the individual equipment, the processing of the collected data and the analysis of the times and methods for ordinary maintenance. In this way it is possible to plan on time the supply of necessary spare parts, date of maintenance and the equipment required.

Service department:

+7-707-686-44-65

IF YOU DON'T FIND THE RIGHT OPTION, DON'T HESITATE TO CALL US.

WE WILL HELP YOU TO FIND THE RIGHT EQUIPMENT.

QUICK PRICE CALCULATION FOR INDUSTRIAL EQUIPMENT IN 2 STEPS

×