Vertical agitators

Vertical mixers (agitators) have a wide range of applications. These include the oil and gas, chemical, pharmaceutical, food and beverage, wastewater treatment, production of paints, detergents, ceramics, and much more. The size of the mixer is determined by the torque (power depends on the number of revolutions). Vertical mixers are a flexible solution that allows you to install any type of impeller, operate at high or low speed. They can be supplied with or without a sealing system. Sealing options are common to the entire model range. These mixers are not suitable for use in tanks with a diameter of more than 10 m. ASCO PUMPS offers you to buy mixers with top connection (vertical mixers), which are represented by low-speed mixers with gearbox, high-speed mixers without gearbox, mixers with high-speed turbine stirrer.

Side-entry mixers

Side-entry mixers are available in low-speed and high-speed models. They are used for simple applications and storage tanks, particularly on large tanks. They are always equipped with a mechanical seal. Not suitable for highly viscous products. They are sized according to the installed capacity, but the parameters on the basis of which they are selected are the throughput to be produced.

Portable agitators

Static inline mixers

A static mixer is the simplest and most economical device for achieving close mixing of two or more components. The goal is achieved by deflecting the flow of the liquid from the currents flowing through it. The main applications are in the water treatment industry, the paint and varnish industry, the food industry and smoke/gas control plants.

Performance depends on the relationship between the flow rate, viscosity and density of the liquids to be mixed; based on this data and experience in many applications, we select different types and configurations of elements.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

6 reasons to buy mixers or agitators at ASCO PUMPS

- A wide range of different types and designs of mixers.

- Mixing of various products.

- Production of non-standard mixers depending on customer requirements.

- Knowledge of the production process is based on in-depth knowledge of the product's application.

- We select the right type of impeller, choose the number of impellers, their diameter and speed based on the size of the tank.

- We do not produce mixers according to the customer's design, because we are fuProduction of non-standard mixers depending on customer requirementslly responsible for the selection and production.

Articles

The last news and articles

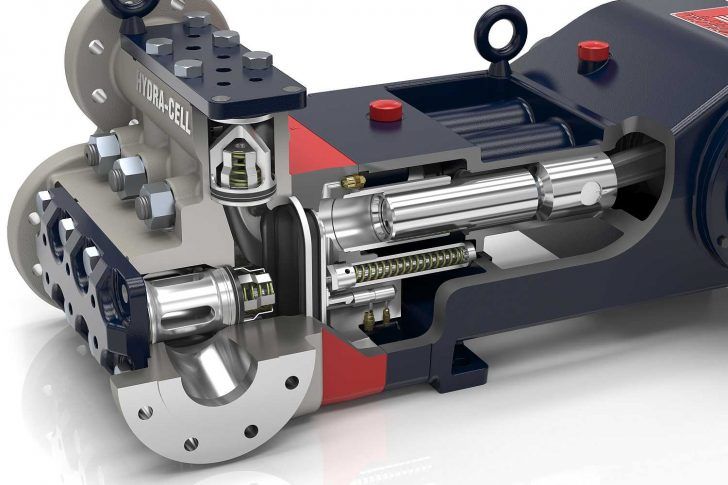

ATEX reciprocating pump for viscous liquids with suspended solids

More details

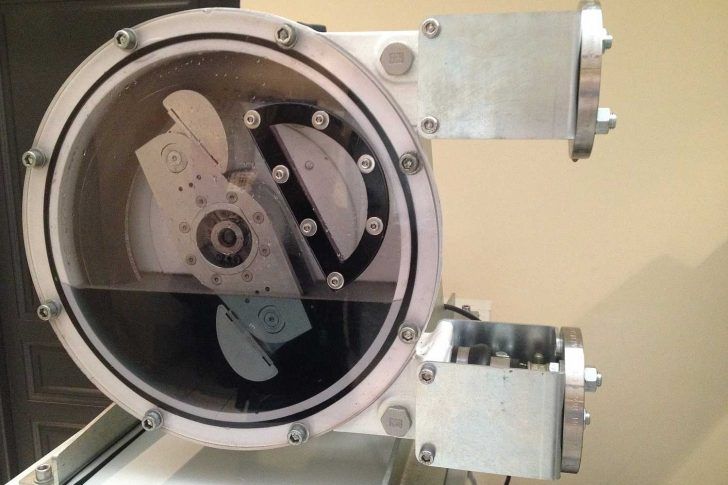

Innovations in the design of the VPH peristaltic pump

More details