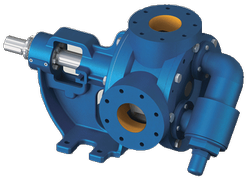

Internal eccentric gear pump

The internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Heavy-duty gear pumps

Heavy-duty gear pumps solve the toughest applications and ensure maximum flow rates when emptying large tanks. The foot-mounted design of the pump allows the use of various types of mechanical seals without changing the design of the pump itself (Universal Seal series). A large bearing cup located at the rear of the pump allows the installation of any seal, from a conventional stuffing box to a double mechanical seal.

Motor speed gear pumps

Viking's motor-speed industrial pumps are designed for increased performance by using double ball bearings and a direct motor-pump arrangement. Reliable mechanical seals and gaskets eliminate leakage and extend pump life.

Helical gear pumps

Helical gear pumps are used for pumping viscous liquids at low speeds. These pumps work same gear pumps. Pump shaft transmits circular movement with own gear to other gear on inverse side. While gears leave from other, liquid get full between gears. While gears become close, this liquid moves with rotary motion to outlet. We can have pressure until 20 Bar according to liquid viscose.

Also they are good in where there is a need for uninterrupted capacity for less viscous and medium pressure places.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

4 reasons to buy a gear pump from ASCO PUMPS

- We offer robust, reliable and yet economical pumps.

- We offer compact pumps with various options for pumping a wide variety of liquids.

- We always strive for the perfect quality of our products.

- We have a qualified approach to the needs of our customers.

Articles

The last news and articles

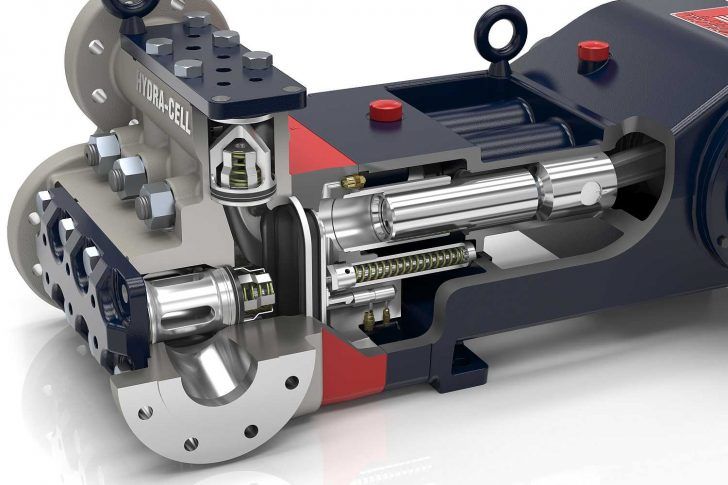

ATEX reciprocating pump for viscous liquids with suspended solids

More details

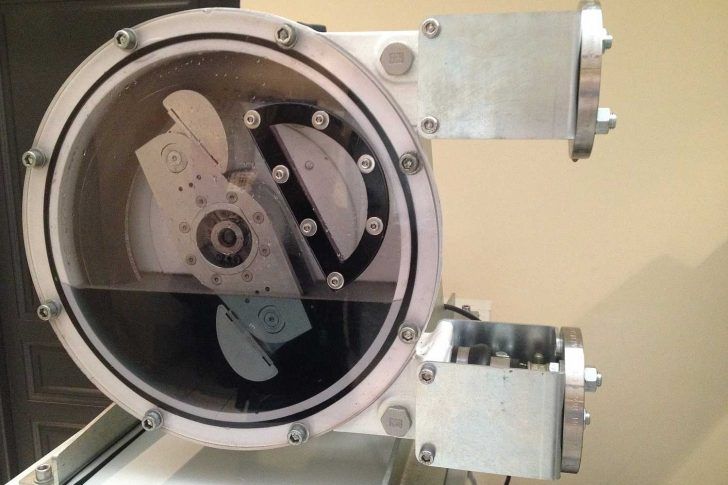

Innovations in the design of the VPH peristaltic pump

More details