Email: office@ascopumps.kz

Kazakhstan

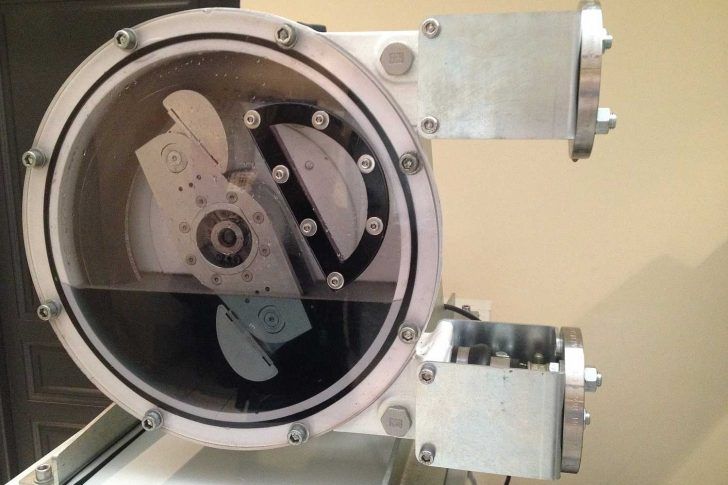

Innovations in the design of the VPH peristaltic pump

Innovations in the design of the VPH peristaltic pump

VALISI PUMP engineers have developed an updated design of the VPH series peristaltic pump.

The pumps of this series feature a new design of the pump head and ports:

- New EPDM O-ring sealing the pump head

- New brackets with laser engraved Valisi logo

- New connections (only a few sizes)

- A tight connection is ensured

- New rotor design: lighter and better shaped

- Sleeve welded to the flange

- Thicker bushing, less wear and tear

- Easier maintenance of the pump

- Machined steel shoes with less roughness and better smoothness

- Pump size marked with laser

IF YOU DON'T FIND THE RIGHT OPTION, DON'T HESITATE TO CALL US.

WE WILL HELP YOU TO FIND THE RIGHT EQUIPMENT.

QUICK PRICE CALCULATION FOR INDUSTRIAL EQUIPMENT IN 2 STEPS

×