AVF with worm gear reducer

AVF with worm gear reducer. They are mainly used in closed containers with a volume of about 15 m3. With different types of seals. Power up to 4 kW.

AVC bevel gear reducer

AVC bevel gear reducer. They are used on large tanks where horizontal positioning of the motor is required.

AVS coaxial gear or epicyclic reducer

AVS coaxial gear or epicyclic reducer. Mainly used in open containers. Vertical motor design with external output shaft. Large sizes are available with an additional bearing for longer shafts.

AVL with parallel axis reducer

AVL with parallel axis reducer. A high-quality solution for open or closed vessels of various sizes. The mixer shaft is mounted directly into the hollow shaft of the gearbox. Vertical position of the motor.

AV - fast without gearboxes

AV is a high-speed mixer. The engine speed is 700/900/1400 rpm. The model is available with/without INOX flange and seal. Mechanical sealing is available for pressure vessels. It is used for small containers.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

6 reasons to buy mixers or agitators at ASCO PUMPS

- A wide range of different types and designs of mixers.

- Mixing of various products.

- Production of non-standard mixers depending on customer requirements.

- Knowledge of the production process is based on in-depth knowledge of the product's application.

- We select the right type of impeller, choose the number of impellers, their diameter and speed based on the size of the tank.

- We do not produce mixers according to the customer's design, because we are fuProduction of non-standard mixers depending on customer requirementslly responsible for the selection and production.

Articles

The last news and articles

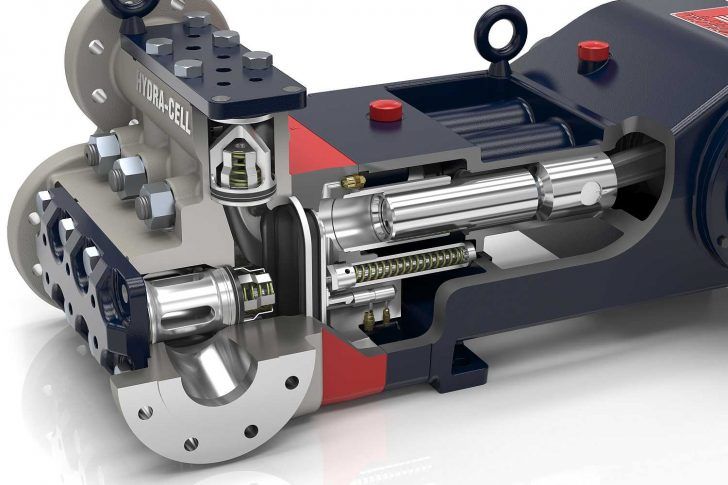

ATEX reciprocating pump for viscous liquids with suspended solids

More details

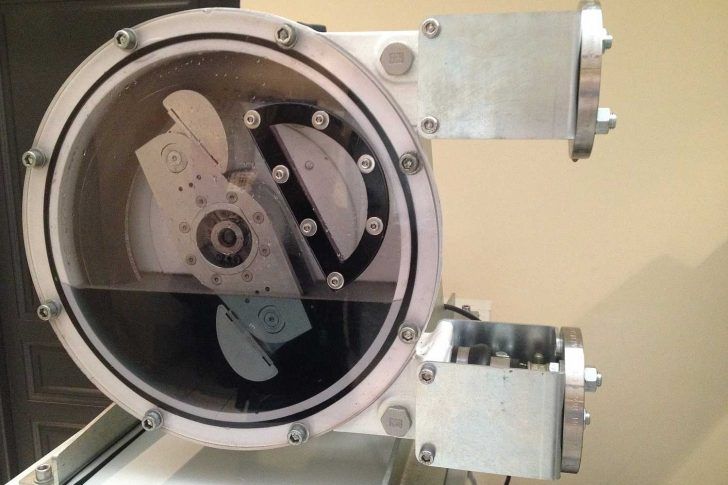

Innovations in the design of the VPH peristaltic pump

More details