Flex-Mix™ Processor

Flex-Mix™ Processor is a high performance batch production plant for preparation of demanding mixes such as high viscosity liquids, emulsions and mixes with a high content of dense ingredients. It is an inclined tank with a high-power paddle mixer mounted at the bottom. This mixer works partly as an axial mixer and/or partly as an in-line mixer.

BASIC PROCESS TYPES:

- Highly-effective emulsification

- Pasteurization (direct/indirect heating)

- Vacuum mixing – deaeration

- Dispersion of dense ingredients

Advantages

- Overall very high consistency and reproducibility

- Proven functionality with excellent product quality

- Does not destroy granular particles

- Fast processing time

- Two Flex-Mix units ensure continuous production flow

- Flex-Mix Processor can be used for a wide range of products

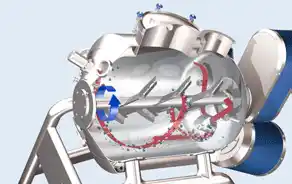

Operating Principle

Flex-Mix™ Processor is a tilted tank with a high shear bottom mixer. This mixer works partly as an axial mixer and/or partly as an in-line mixer. It creates an axial flow that is re-circulated in the tank with a surrounding mixer and/or booster pump, which is used to bypass and recirculate the flow through the tank. Parallel flow returns to the reservoir and the inclined reservoir ensures that the fluid does not rotate in the reservoir (forced swirl). The tank is also equipped with a slow rotating agitator to ensure thorough mixing and homogeneous mixing of the product particles while creating an axial flow that feeds the lower impeller. If a scraper blade agitator is installed, it ensures that the product does not burn or stick to the tank wall when indirectly heated (tank with cooling/heating jacket). In case the product is heated, the reservoir can be supplied under pressure. Powder is transported to the tank through a special powder feed valve with the help of a vacuum. Powder/air mixture is directed into the liquid below the surface of the liquid. Air/gas is removed by a vacuum pump. Large free surface of the liquid ensures efficient deaeration of the product. Unlike traditional mixing, this usually includes air during mixing. This will help reduce oxidation and improve product quality and consistency. Powders or other solids can also be added through the slots located in the top of the tank.

Flex-Mix™ Processor is a tilted tank with a high shear bottom mixer. This mixer works partly as an axial mixer and/or partly as an in-line mixer. It creates an axial flow that is re-circulated in the tank with a surrounding mixer and/or booster pump, which is used to bypass and recirculate the flow through the tank. Parallel flow returns to the reservoir and the inclined reservoir ensures that the fluid does not rotate in the reservoir (forced swirl). The tank is also equipped with a slow rotating agitator to ensure thorough mixing and homogeneous mixing of the product particles while creating an axial flow that feeds the lower impeller. If a scraper blade agitator is installed, it ensures that the product does not burn or stick to the tank wall when indirectly heated (tank with cooling/heating jacket). In case the product is heated, the reservoir can be supplied under pressure. Powder is transported to the tank through a special powder feed valve with the help of a vacuum. Powder/air mixture is directed into the liquid below the surface of the liquid. Air/gas is removed by a vacuum pump. Large free surface of the liquid ensures efficient deaeration of the product. Unlike traditional mixing, this usually includes air during mixing. This will help reduce oxidation and improve product quality and consistency. Powders or other solids can also be added through the slots located in the top of the tank.

Application

- Production of cheese/processed cheese

- Soups and sauces with dense ingredients

- Fruit jams

- Ice-cream

- Puree and jelly dispersions

- Mayonnaise, sauces and ketchups

- Hand creams, ointments and lotions